Custom Metal Stamping Press Automation Systems

We’re Picking Up What You’re Putting Down!

Process automation in the metal stamping industry utilizes the latest technologies to optimize and streamline various stages of manufacturing. Another aspect of metal stamping automation is the integration of robotic systems for tasks such as part feeding, positioning, and removal. These systems execute these functions with precision and speed, contributing to improved accuracy in the stamping process. With the implementation of feedback sensors and cameras for real-time quality control adds an extra layer of reliability, ensuring that only high-quality parts make their way through the production process.

In essence, process automation in the metal stamping industry not only boosts efficiency and productivity but also enhances precision and quality control, positioning manufacturers at the forefront of modern and competitive manufacturing practices. Lastly, it helps with employee shortages or skill level gaps. One employee can oversee several presses in a production line to ensure optimal output and yield to the end product.

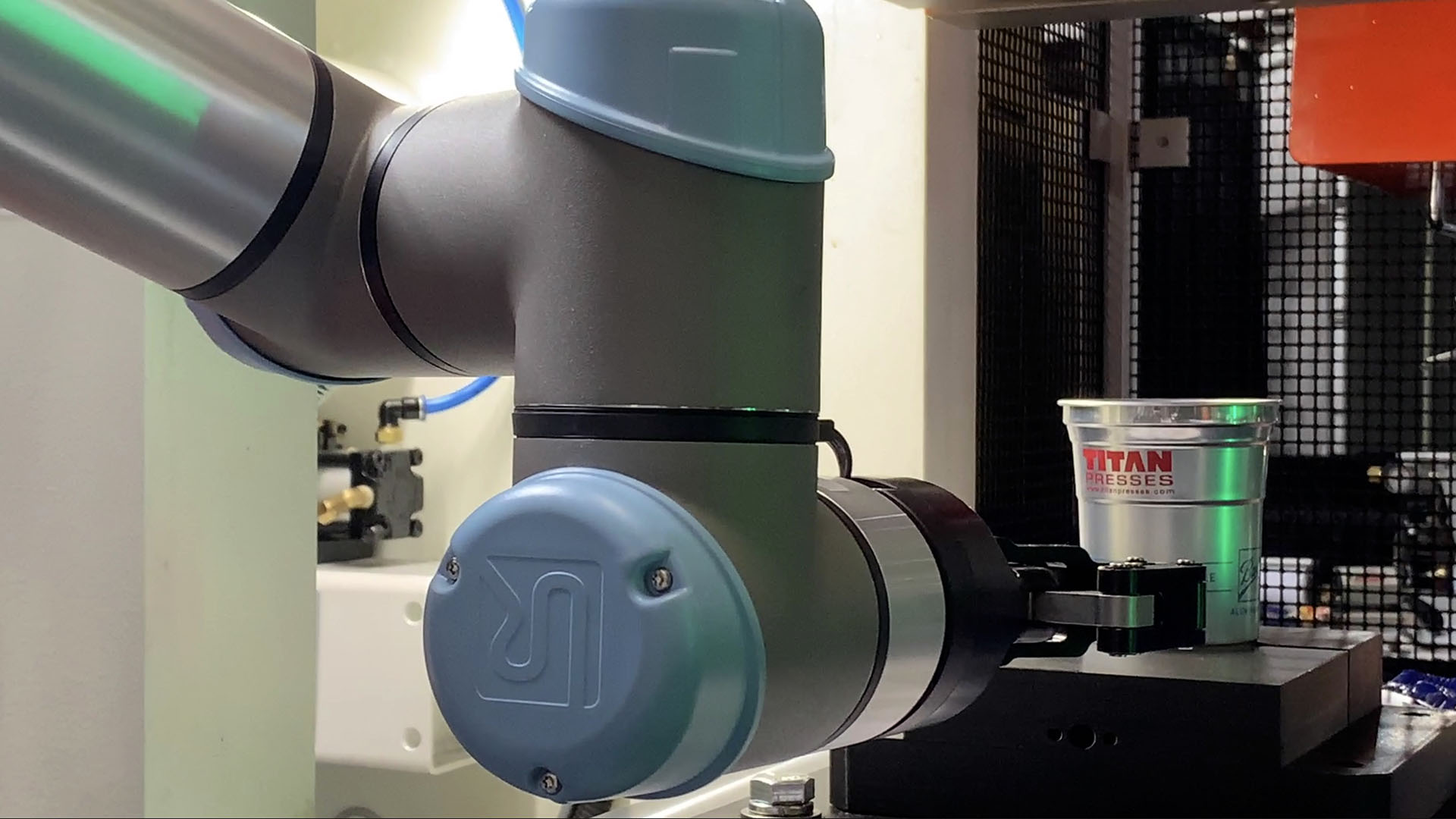

Robotics Automation Integration

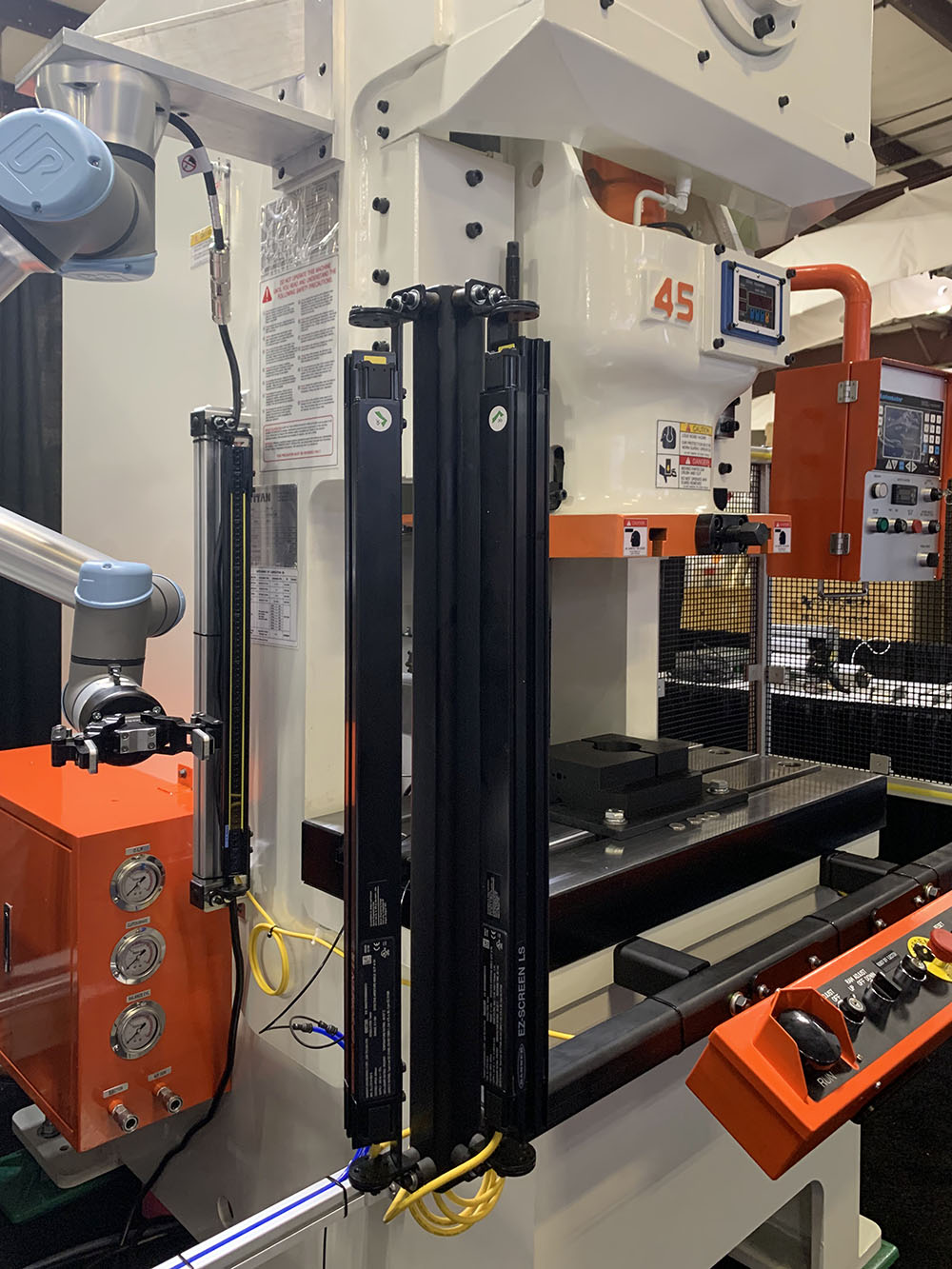

Robotics integration has revolutionized the metal stamping industry by introducing advanced automation to enhance efficiency and precision. Robots minimize manual labor, streamlines the production line, and contributes to a more seamless manufacturing operation. At the same time, it minimizes human risk by allowing the workpiece to enter dangerous parts of the press. Additional safeguarding and sensors provide feedback to the control panel which signals to the robot how to perform tasks efficiently and safely. Handling parts with a robot comes in many different forms and by using suction, servos and electronics you can perform many tasks to keep your production line optimized. Their ability to execute these processes with speed and accuracy significantly improves overall efficiency in the metal stamping workflow.

Less Machine Downtime

Investing in your production line will help in many ways. Being able to repeat tasks quickly and precisely is the name of the game. Time is money and if you are spending most of it making adjustments or cobbling procedures together you will benefit from a fully automated stamping press designed and built to your specifications. Here are some benefits of automated systems in the manufacturing industry.

Increased Quality

Increased Flexibility

Increased Throughput

Optimize Productivity

Reduce Human Error

Maximize Employee Safety

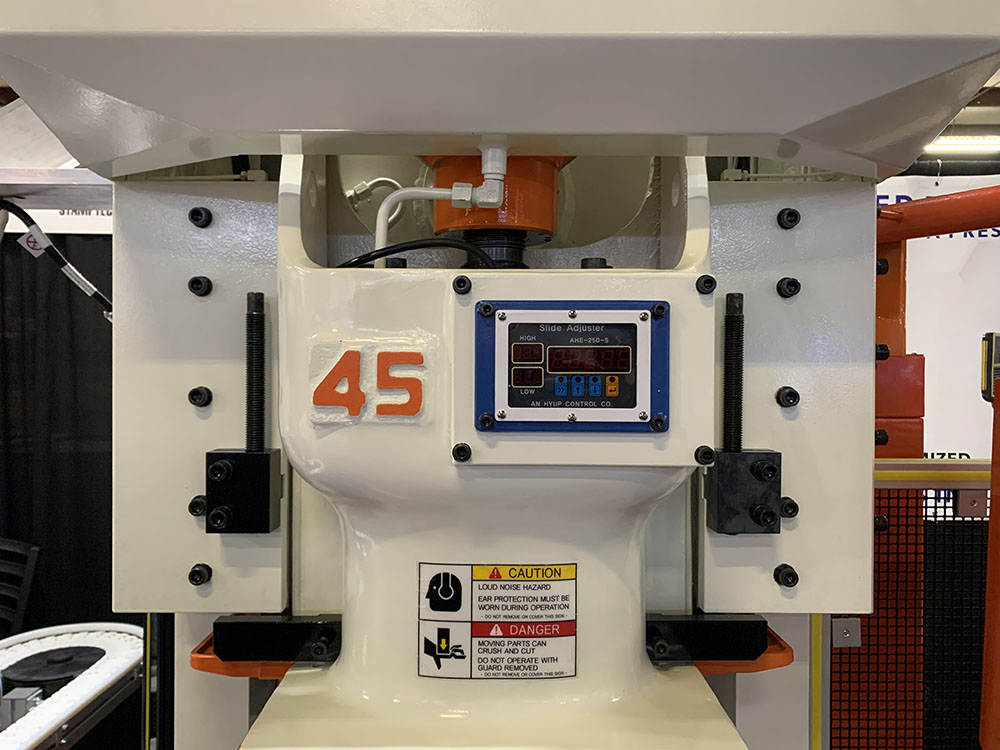

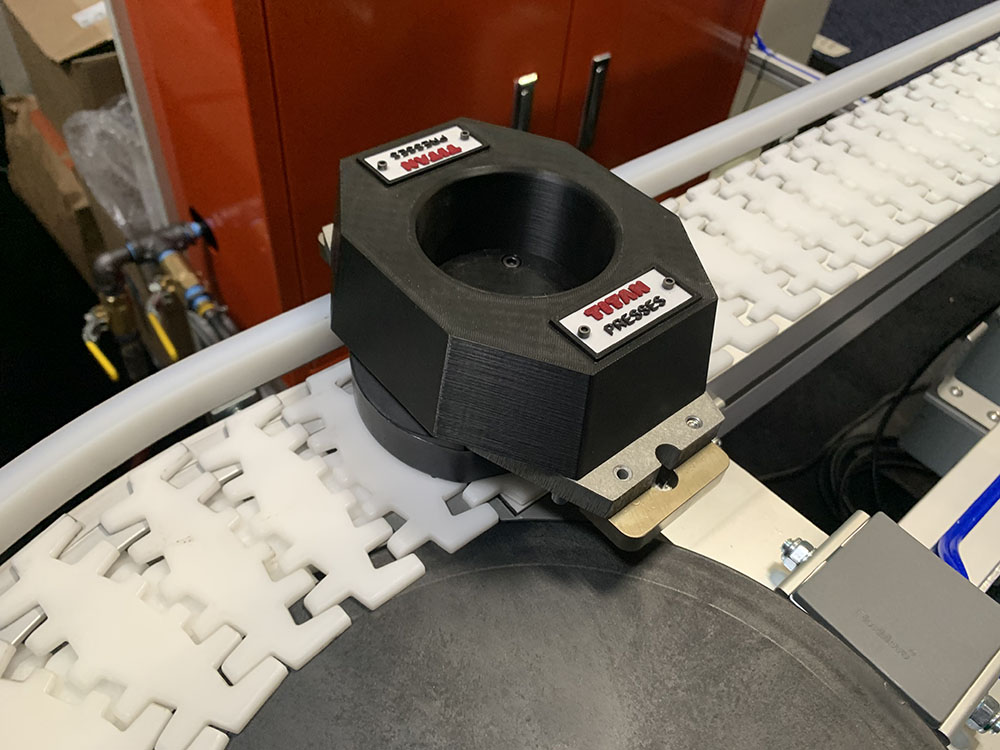

Components in Metal Stamping Automation

Metal stamping press automation involves the use of automated systems and technology to streamline and enhance the efficiency of metal stamping processes. There are many moving parts that go into automating a production line. From feeders and decoilers to safeguarding and conveyors, StampTech can help you customize your process to give you optimal results. Here is a summary of key aspects related to metal stamping press automation.

What’s the Bottom Line?

Metal stamping press automation offers numerous benefits, including increased efficiency, precision, and safety, along with the ability to adapt to various production requirements. It plays a crucial role in modernizing and enhancing the competitiveness of metal stamping operations in the manufacturing industry.

Quality Control

Automation systems can include sensors and cameras for real-time quality control. This helps in detecting defects or deviations in the stamped parts, ensuring that only high-quality products are produced.

Data Monitoring and Analysis

Automation allows for the collection of data related to production metrics, machine performance, and quality control. This data can be analyzed to optimize processes, predict maintenance needs, and improve overall efficiency.

Safety Features

Automated metal stamping systems are designed with safety features to protect operators and ensure compliance with safety regulations. These may include barriers, light curtain scanners, and other emergency stop mechanisms.

Cost Efficiency

Investment in automation technology leads to long-term cost savings through increased production rates, reduced labor costs, and minimized material wastage.

Flexibility

Automation in metal stamping press systems provides flexibility in handling different materials, part sizes, and production volumes. This adaptability is crucial for meeting diverse customer demands.

Environmental Impact

By optimizing material usage and minimizing waste, automated metal stamping contributes to a more sustainable and environmentally friendly manufacturing process.